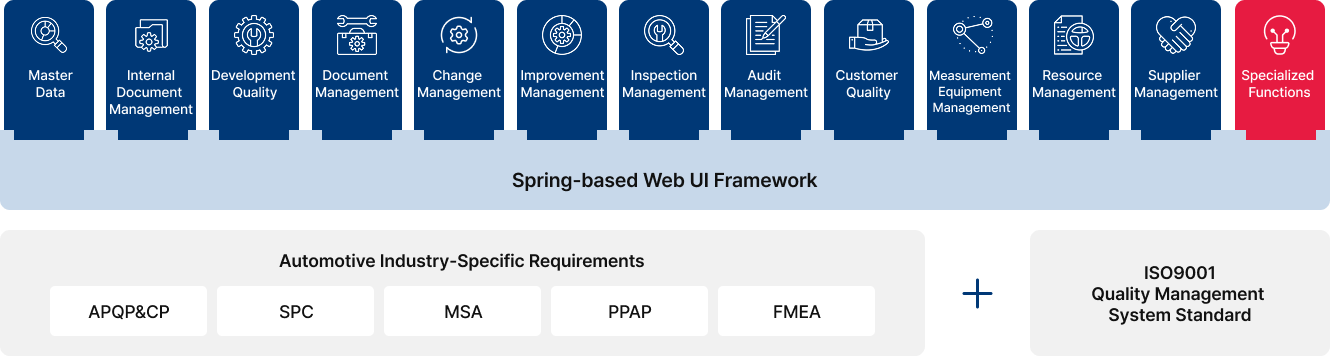

Key Features

Provides flexibility and scalability to quickly respond to process changes, with the ability to add functions and apply upgrades based on standard architecture.

Quality Standards / Document Management

-

Item-specific quality standard setting

-

Inspection/test criteria and item setting

Defect Analysis / Improvement Management

-

Recording and tracking quality issues such as product defects and customer complaints

-

Support for root cause analysis and improvement

Quality Certification / Document Management

-

Internal and external quality certifications/audits management

-

Quality document creation/request/approval management