Key Features

Integrates with various material handling equipment to manage transport instructions, optimize routing, and control dispatching rules.

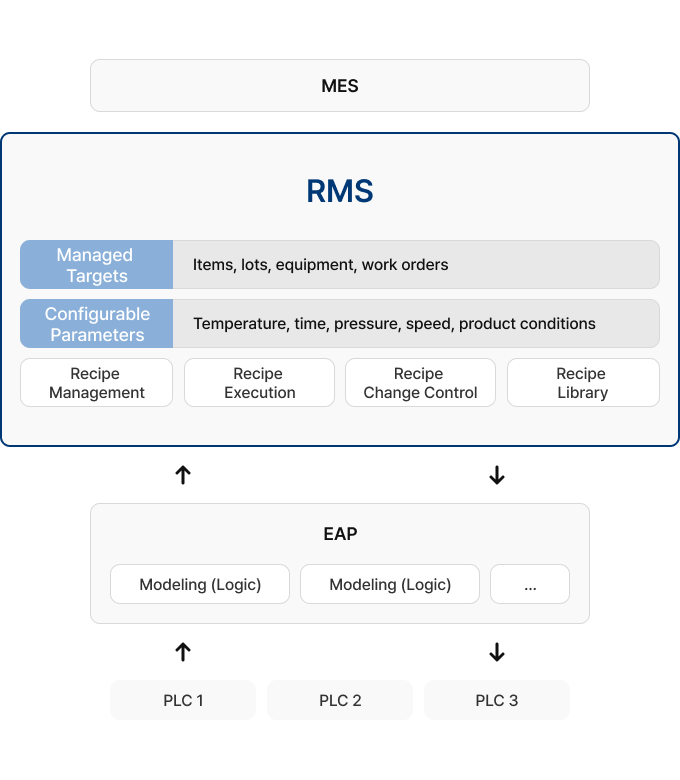

Recipe Master Data Management

-

Recipe master data and revision history management

Recipe Comparison and Validation

-

Comparison between equipment and RMS recipes with warning and interlock functions

Parameter Specification Management

-

Upper and lower specification limit control for recipe parameters

Recipe Upload & Download

-

Real-time recipe upload & download

Report

-

Recipe management status and data change trends

Recipe Registration and Version Control

-

Automatic version creation upon recipe change

-

Change history viewing function

-

Version-to-version change comparison

Approval and Change Control Functions

-

Approval process applied for change requests

-

Access permission settings by user groups

-

Approval history viewing

Automatic Transmission with Equipment Integration

-

Automatic transmission linked with MES work orders

-

Equipment-specific communication protocol support

-

Automatic equipment setting status monitoring