We begin

by listening to the real voice of frontline workers.

Company A

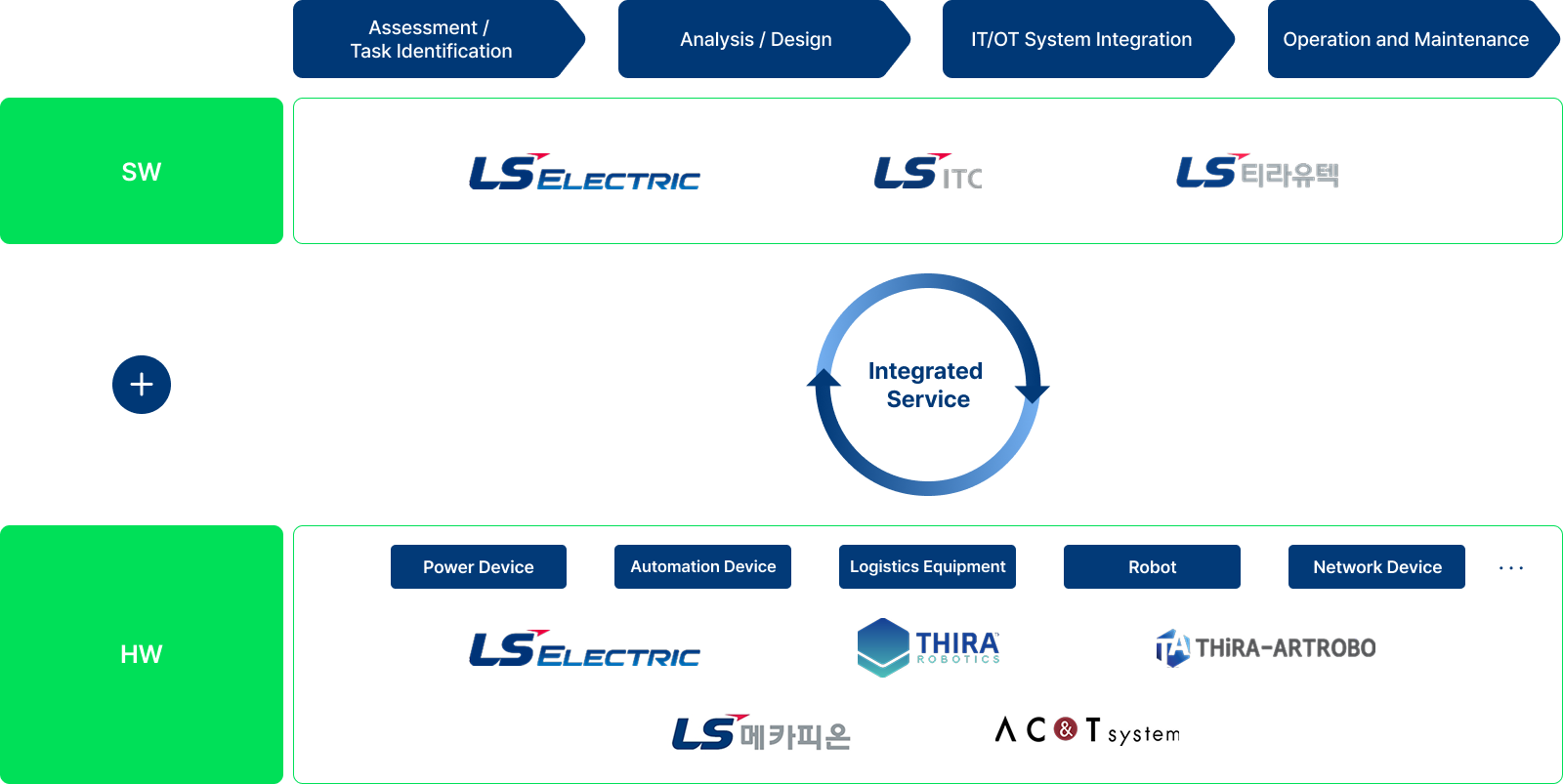

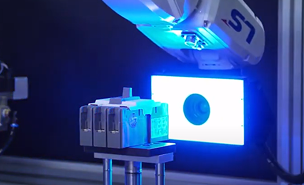

"There are so many required technologies that coordinating and planning across multiple vendors is challenging."

Company B

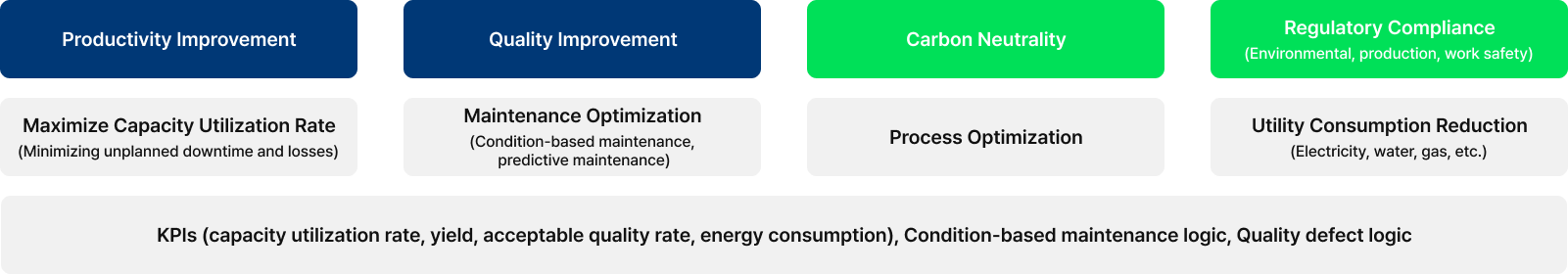

"With ESG becoming a key priority, we want to implement a smart factory that also enhances energy efficiency."

Company C

“We prefer a partner with manufacturing expertise rather than a consulting or IT firm to lead the implementation."