Key Features

Generates condition reports through automatically collecting motor operation data and rule-based diagnostics grounded in operational and management know-how.

As-Is

- Overall Alarm

- Manual Work Based on Maintenance Personnel Experience

(Data Collection, Analysis, Report, Repair History Tracking)

To-Be

- Parameter Alarm

- Auto Data Collection

- Diagnosis Rule Evaluation

- Auto Reporting

- Digitalization of Maintenance Information

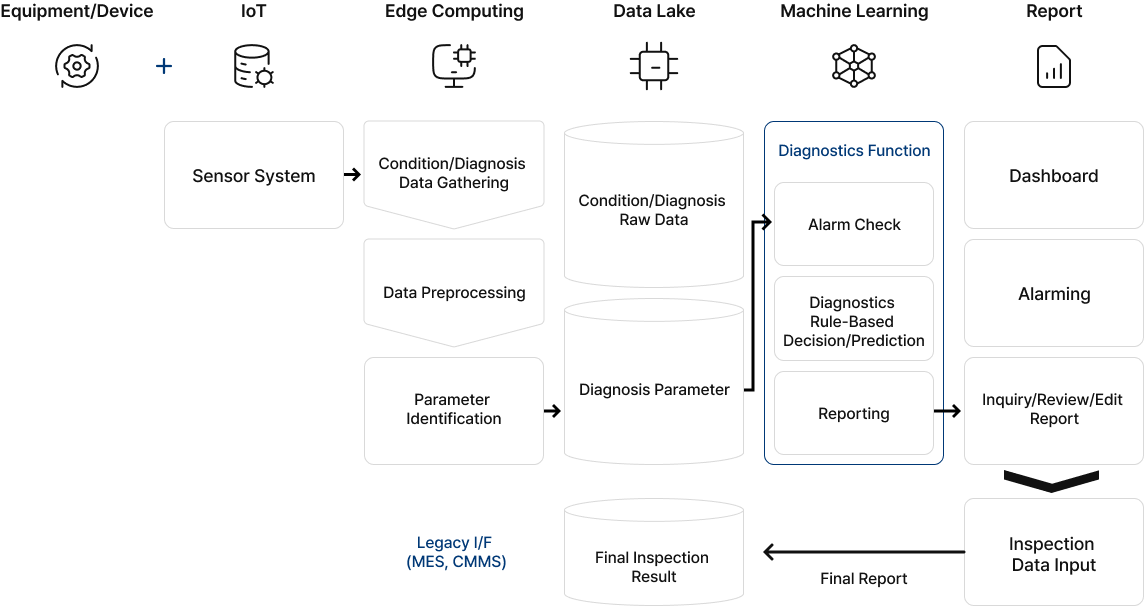

Motor SCADA Data Flow

Automatic Data Gathering

-

Sensor consulting, implementation, diagnosis

-

Equipment/IoT data gathering

-

Real-time analysis on Edge

Fault Diagnosis Rule Generation

-

Equipment standard rule setting

-

Optimized rule deployment

-

Rule management by experts

Monitoring & Fault Diagnosis Report

-

Condition & diagnostics monitoring

-

Auto scheduled inspection reporting

-

Auto fault diagnostics reporting