Key Features

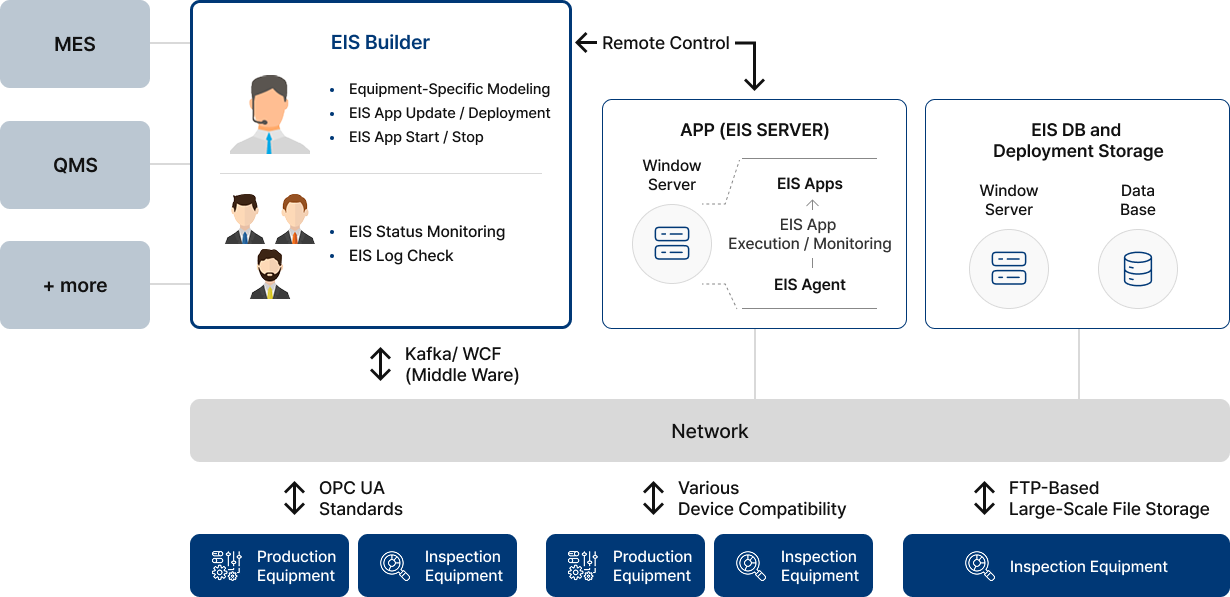

Provides the interface between MES and equipment for data acquisition and remote control.

EIS Application Architecture

Standardized Modeling

with EIS Builder

-

Device-based information modeling

-

Group management by device model

-

Integrated management covering version control, deployment, execution, monitoring, and more

Interface Process Management via

EIS Agent

-

EIS App server deployment and file management

-

System performance monitoring

-

Remote execution integrated with EIS Builder

Provision of Various APIs

with EIS Framework

-

Transaction processing through workflow engine

-

Provision of diverse libraries and standard APIs for EIS App development