Key Features

Manages transport instructions, route optimization, and dispatching rules in coordination with various logistics transport equipment

Equipment interface (AMHS*)

- Storage :

Stocker*, Load Port / Buffer Station*

- Transfer Machine :

OHT*, AGV, ...

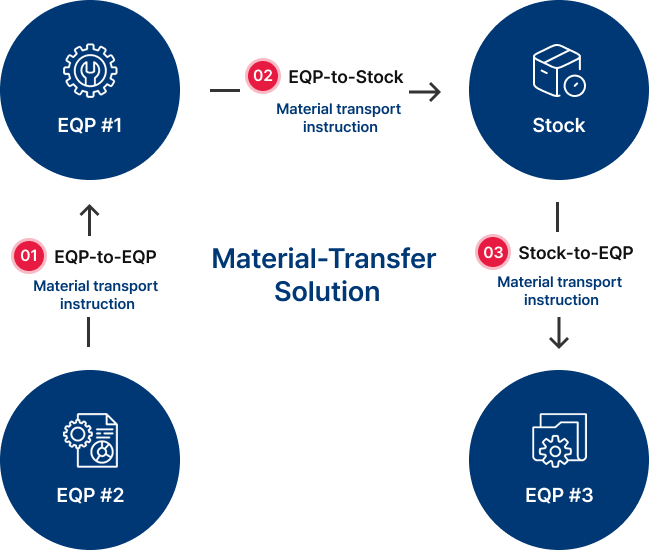

Material transport instruction management

-

Instruction error handling and exception management

-

Queue processing and optimization (priority list, resource allocation, etc.)

Transport route optimization

-

Carrier location management (location tracking, etc.)

-

Carrier specifications and status management (size, staging location, etc.)

-

Route classification and optimization (destination type, priority, etc.)

- * AMHS (Automated Material Handling System Equipment): Equipment for automated material transport

- * Stocker: Automated storage system for temporarily holding materials

- * Load Port / Buffer: Interface device for material transfer between equipment and AMHS

- * OHT (Overhead Hoist Transport): Transport system that moves along overhead rails

Flexible IT Architecture

-

Open architecture for system integration (DB-independent)

-

Modern IT platform based on Java

-

Integrated development employment and deployment function for customization

Industry-Specific Modular Functions

-

Modularization of MCS functions based on SEMI/SEMATECH standards for the semiconductor industry

-

Modularized support for specialized equipment based on experience in semiconductor, FPD, and secondary battery packaging industries

-

Independent functional module structure

Scalability-Oriented Design

-

Supports various communication protocols such as Web Service, TCP/IP, and TIB/RV

-

Supports database scalability (userdefined columns, tables, etc.)

-

Supports rule-based business logic extensibility