Goals

Delivers efficient system integration services based on validated solutions and reference models.

Traditional SI Approach

-

High Cost

- High costs and extended implementation period

-

Increased Complexity

- Lack of standardization causing ongoing maintenance burdens

-

Limited Scalability

- Flexibility and scalability of the system are restricted

SolutionBased System Integration

-

Faster Deployment (Shorter Time-to-Market)

-

Cost Efficiency

-

Reliability (Proven & Stable Solutions)

-

Simplified Maintenance

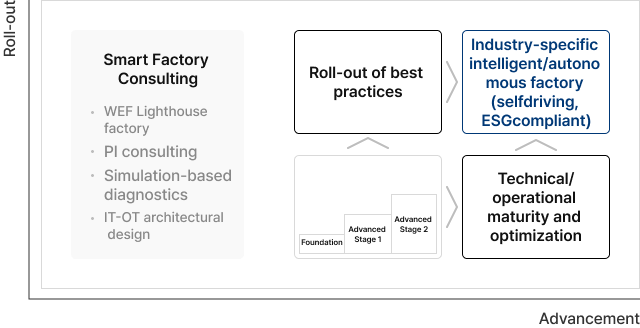

ReferenceBased System Integration

-

Best Practice Applied

-

Lower Risks

-

Expansion Across Similar Industries

Offering Method

Offers flexible implementation models—standalone, integrated, or unique requirement-based—customized for the customer’s environment.

Standalone Solution Offering

IT

Independent provision of individual solutions such as MES, QMS, and WMS

OT

Independent provision of solutions such as PLC/HMI and manufacturing automation

Benefit

Flexible adoption and lower initial implementation costs

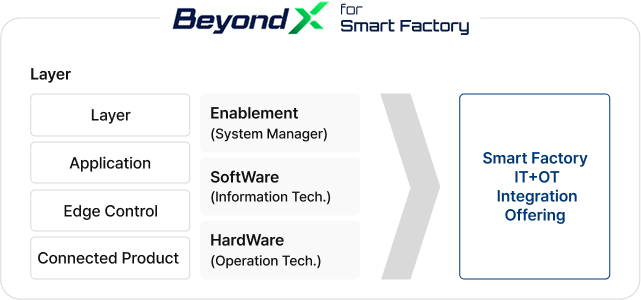

Integrated Platform Offering

IT + OT

Integrated process automation based on manufacturing SW and HW within a single platform

Benefit

Increased operational efficiency, consistent data management, and easy scalability

New-One System Offering

Case-Based Integration

Customized system integration for intelligent/autonomous factories

AI/ML models provided through data analysis

Benefit

Risk minimization and stable implementation based on proven best practice cases

Key Differentiators

Drives manufacturing innovation through rapid deployment, industry-specific solutions, AI/ML scalability, continuous maintenance support, and seamless IT-OT integration.