AI-Based Vision Inspection (Deep Learning System)

System Overview

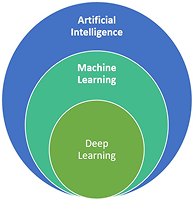

※ Deep Learning-Based Inspection System

-

AI-based technology

-

Autonomous learning from image data

-

An algorithm developed using open-source

framework

-

An algorithm developed and owned

by LS ELECTRIC

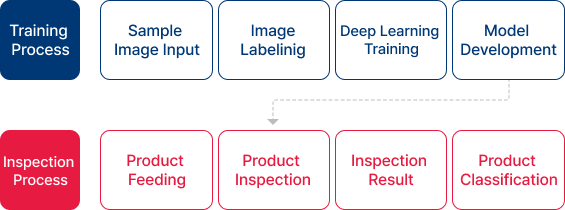

※ Deep Learning Inspection Method

※ Key Features of the Deep Learning Inspection System

(Compared to manual or rule-based inspection systems)

-

Capable of inspecting irregular or non-standard products

-

Reduces labor and time required for reprogramming when new

defect types are introduced

-

Eliminates the risk of inconsistent or inaccurate judgment due to

fatigue or emotional factors

Smart Logistics

An advanced logistics automation system that utilizes AGVs (Automated Guided

Vehicles) for parts supply and product transport on automated assembly lines. The

system enhances musculoskeletal safety and establishes a foundation for efficient

logistics workforce management.

-

System Configuration

Parts storage conveyor / Box lifter / In-out conveyor / ATC for parts box supply / AGV system / AGV auto charging

- Development Timeline

Review: 1 month, Manufacturing: 4 months, Commissioning: 1 month

- Investment Benefits

Labor savings (2 personnel), Smart logistics factory, Prevention of safety incidents and musculoskeletal disorders

Product Transport System Features

-

Centralized AGV control, Autonomous AGV navigation

-

Automated logistics of parts and semi-finished

goods via AGVs

-

Automated box loading and unloading at ATC using lifters

-

Automated parts box supply and retrieval

-

Automatic AGV charging via auto chargers

Parts Supply System Features

-

Cartesian robot application technology

-

Position control via PLC

-

Automated part supply and stacking using

Cartesian robots

-

Integration with AMRs (Autonomous Mobile

Robots) for advanced logistics automation

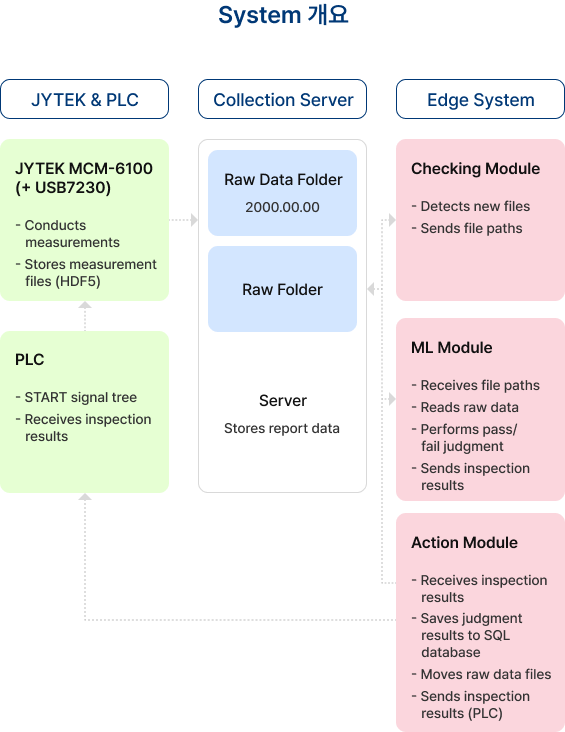

AI-Based Noise Inspection

Applied Technologies

-

Microsoft Azure IoT Edge:

Evaluates inspection results and

stores data

-

PC - Data Acquisition:

Measures and collects data

-

HDF5 File Format: Minimizes

the volume of stored data

Gap Welding Automation

Applied Technologies

-

1) Integrated control of vision system, robot, and laser

welder

-

2) Current supply system control

-

3) Feedback control of overcurrent test bench via RFB (Realtime Feedback) system

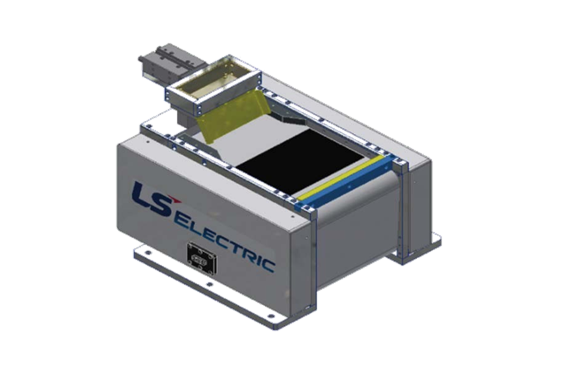

BPS (Bin Picking System)

A system that enables the supply of irregularly

shaped parts for assembly, inspection, and

other manufacturing processes

Key Features

-

2D, 3D Vision Camera Application for Picking

Atypical Parts

-

In-House Developed SFS(Smart Feeding System) Applied

- Customized to fit part sizes and shapes

- Automatic model change

Equipment Examples

SFS(Smart Feeding System)

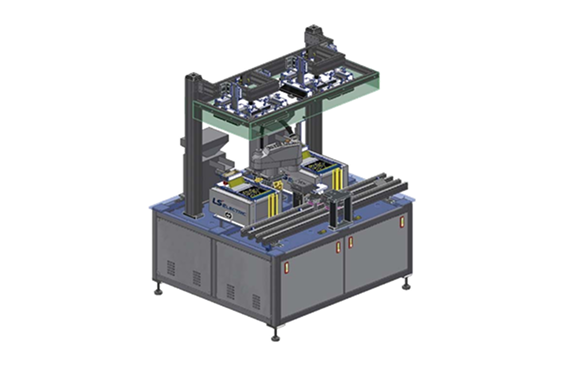

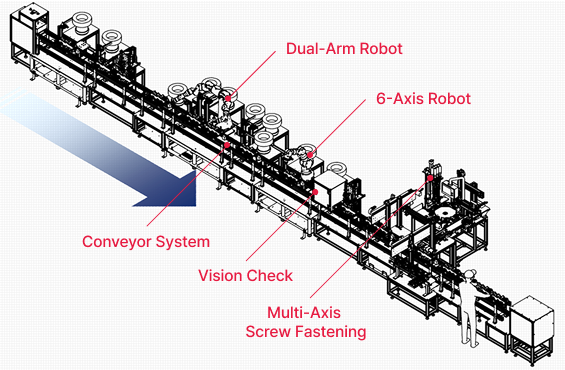

Automated Assembly Equipment

An automated assembly line utilizing dual-arm

and 6-axis robots to assemble parts and fasten

screws.

The system verifies component assembly and

screw fastening status to determine pass/fail

results, enabling one-person operation.

Equipment Examples

Applied Technologies and Features

-

Dual-Arm Robot, 6-Axis Robot, and Single

Robot position control

- Optimized task allocation through efficient

process analysis

- Gripper design for multi-component

gripping

- Avoidance of robot motion conflicts

-

Maximization of Efficiency based on IE

Principles

-

Fool Proofing with Smart Vision Technology

- Missing part detection and assembly status

verification

-

Multi-Axis Screw Feeding and Fastening

-

Single-Operator Assembly Line Management

Application Areas

-

Automation for Small or Mass Production

of Medium-Sized Parts

-

Automation of Manual Labor-Dependent

Processes

-

Automation of Dust-Generating Parts

Assembly

-

Automation of Multi-Axis or High-Speed

Fastening

-

Vision-Based Inspection for Automated

and Manual Assembly Processes

- Defect detection through motion analysis

in manual processes

-

Productivity Improvement through

Process Analysis

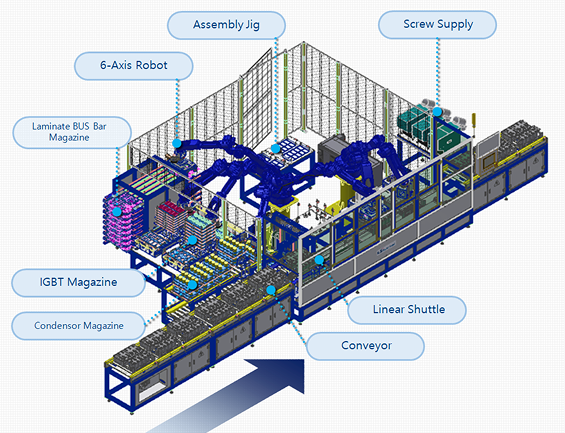

Multi-Tasking Robotics System

An automated system using two 6-axis robots

to assemble and fasten components such as

condensers, IGBT modules, and laminated bus

bars. The system records pre-assembly part

information and screw fastening data, and

links it with frame information to ensure full

traceability.

Equipment Examples

Applied Technologies and Features

-

Multi-Component Assembly Using 6-Axis Robot and

Linear Shuttle

- Precise assembly using assembly jigs

- Tool change tailored for specific components

- Auto screw fastening and data storage

- Ensuring precision of the linear shuttle

-

Parts History Management and Traceability Assurance

-

Auto Alignment and Fool Proofing Using Vision

Technology

- Ensuring accuracy in assembly direction and positioning

- Assembly inspection

Application Areas

-

Automation for Large Products of High-Mix, Low-Volume Production

-

Assembly of Products Requiring Parts History Management and Traceability

-

Automated Assembly for Parts with Difficult

Positioning

-

Parts Assembly Requiring Data Acquisition

and Management for Each Fastening Point

-

Rationalization of Manual Assembly Processes Deemed Difficult to Automate

-

Automation of Assembly Inspection

-

Effective Investment in Processes Requiring

Productivity Improvement